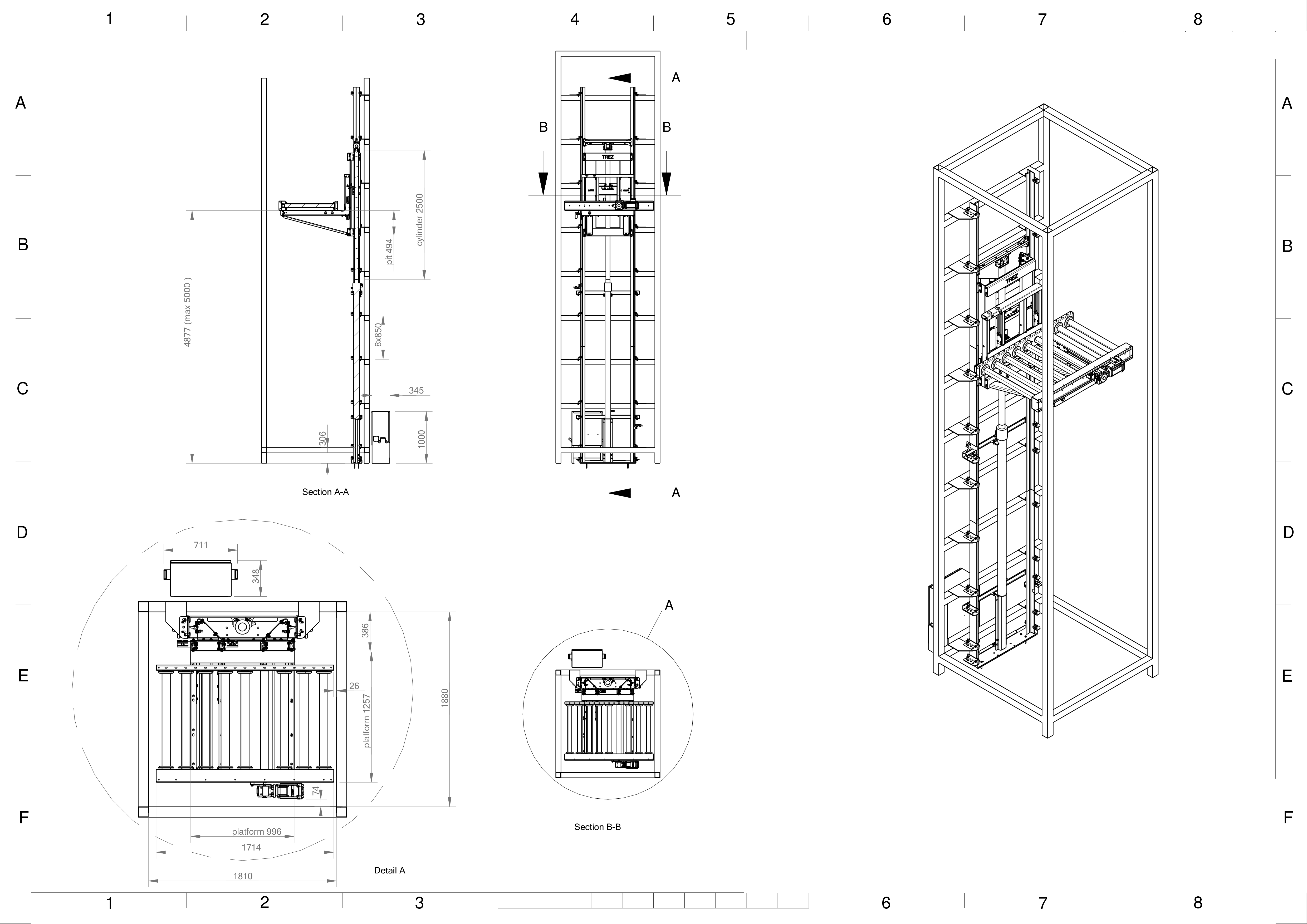

Goods lift with supply/discharge roller tracks

Request

Their interest in a goods lift with supply and discharge lanes arose because the goods have to be transported over various floors and between several warehouses.

Design

Before an offer can be made, the routing must first be determined; usually, the customer has already thought about this, but this is always discussed in detail in order to arrive at a goods lift system that is 100% in line with the wishes and needs of the customer. In this case, a lifting platform with a rotating system was chosen because the entrance and exit are not on the same side of the lift and in this way the number of roller conveyors can be limited. Although the flow of goods usually goes from a to b, a goods lift with bi-directional roller conveyors has been chosen to allow any return flows to run through the same routing.

Tracking of the physical goods is possible via the supplied PLC system.

Installation

Two goods lifts, with a capacity of 1500 kg, bridge the height difference of no less than 5000 mm between the ground floor and the first floor and several factory technicians have been busy for several weeks to build the lifts. In the same period, tens of meters of supply and discharge lanes were constructed by a number of technicians to connect the two goods lifts. In order to be able to work safely at heights, elevating work platforms are used.

After the installation is completed, the goods lift with roller conveyor system is set up and tested extensively. If everything functions optimally, the system is explained to the persons who will work with the system and/or to the responsible person.

Result

A perfectly functioning and safe goods lift system and a satisfied customer who can confidently look forward to the growth of its flow of goods in the coming years. The goods lift system has resulted in an enormous productivity improvement because dozens of walking/travel meters are bridged, which saves the necessary hours in labor costs on a daily basis. Previously it was a coming and going of forklifts between the different warehouses and here too a lot is saved because this is largely a thing of the past and it has therefore become much safer for the employees.

Let’s Work Together

We are happy to advice you and ensure that your lift meets your needs, no bells and whistles that cause unnecessarily high prices. We focus on the origin of the request to create the lift that fits your needs perfectly.