Automated Goods lift and Roller Tracks

Result

An optimally functioning automated goods lift system that efficiently processes the flow of goods on a daily basis. The goods lifts with roller conveyors ensures that the customer can work extremely safe, previously it was a coming and going of forklifts between the different areas and that is now largely a thing of the past. Our customer will be able to process its flow of goods with full confidence in the coming years!

Would you like to know more about this project or our Goods Lifts?

Application

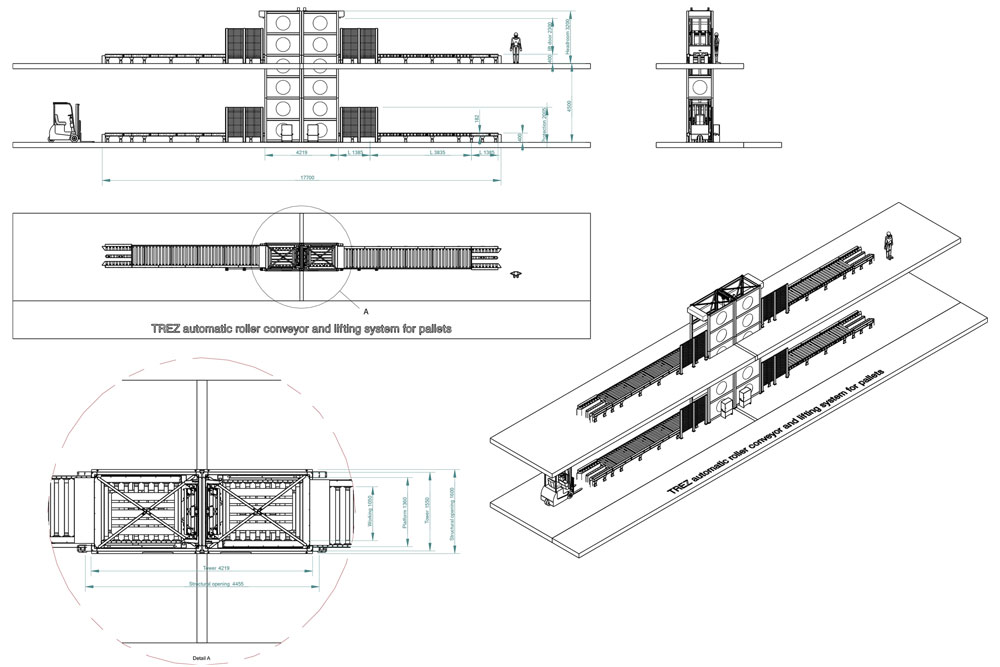

Hublift has been operating in the construction world for many years, both new construction and renovation. We work together with various partners in the construction world and architects, but of course we are always looking for new partners with whom we can achieve a good result together. In this case, we received an application for a goods lift with bi-directional roller conveyors through an architectural firm. A large newspaper printer in Belgium, including owner of the daily newspaper De Telegraaf, wanted to automate their internal logistics so that after the newspapers had been printed, the pallets could be moved efficiently from the 1st floor to loading/unloading docks on the ground floor.

Design

Hublift builds fit-for-purpose Goods Lifts, the design phase is essential to create a good understanding of the customer’s wishes. Once we have a good understanding of the needs, we advise our clients on how the lift can be best used and how the client can work most efficiently with the lift. These considerations are all taken into account in the design of the goods lift. In this project, the goal was for 45 pallets per lift to be moved automatically from the second floor to the first floor. In this case, the flow of goods goes both from a to b and from b to a, which is why a goods lift with bi-directional roller conveyors was chosen so that return flows run through the same routing. Tracking of the physical goods is possible via the supplied PLC system.

Installation

Two goods lift, with a capacity of 1000kg each, bridge a height difference of 4500mm between the ground floor and the first floor and several factory technicians have been busy for several weeks to build the lifts. In addition, during the same period, a number of engineers constructed tens of meters of supply and discharge lanes to connect the two floors via the goods lifts. In order to work safely at heights, aerial platforms are used, among other things.

After installation is completed, the goods lift with roller conveyor system is extensively tested. If everything functions optimally, the system is explained to the persons who will work with the system and/or to the responsible person.

Let’s Work Together

We are happy to give you free advice and ensure that your lift meets your needs. No bells and whistles that cause unnecessarily high prices, as we focus on the origin of the demand to create the lift that fits your needs perfectly.