Goods lifts with person guidance for a thrift store

Result

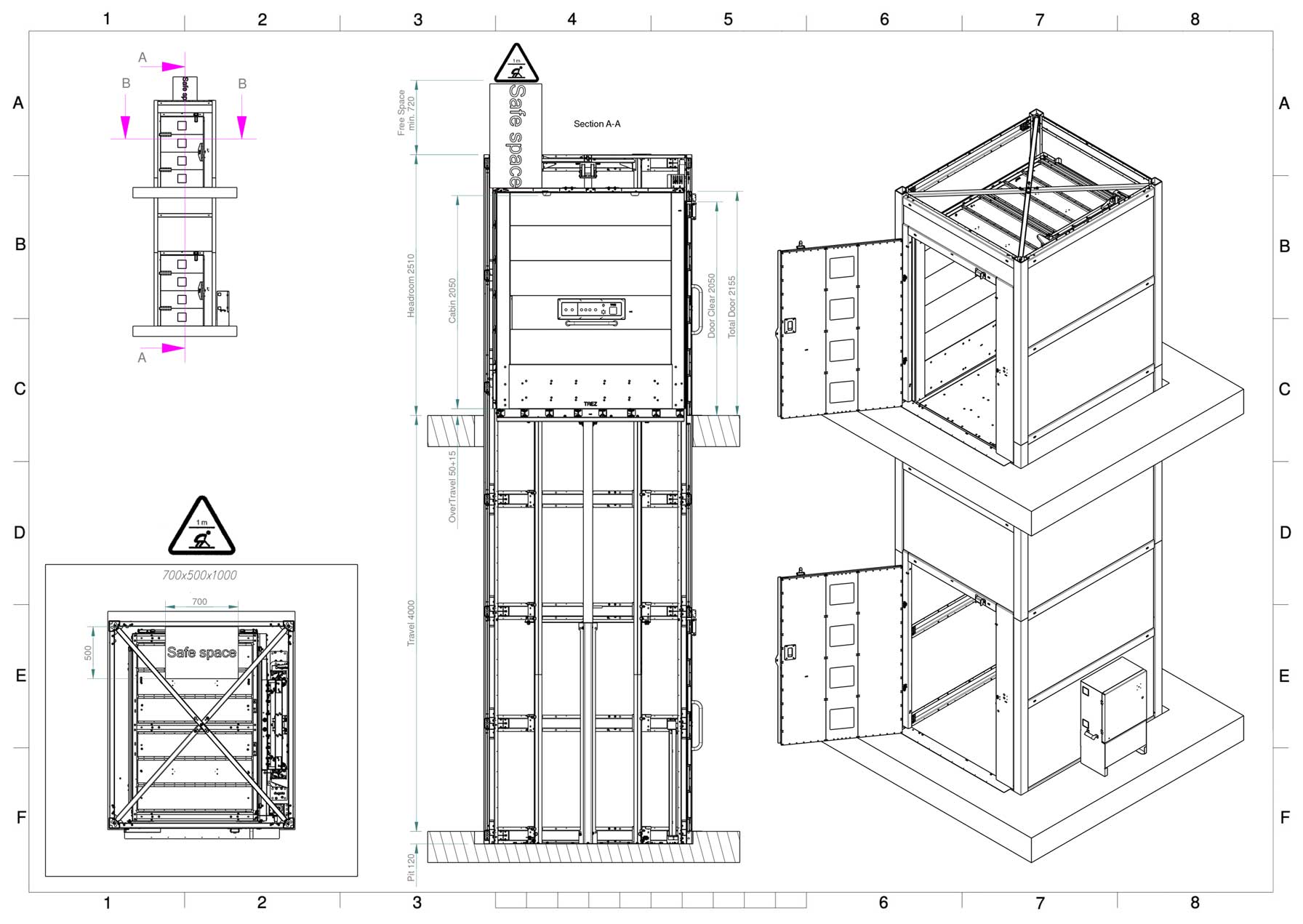

The lift was built to fit precisely into the floor recess already made by the structural engineer. For this purpose, Hublift supplied a self-supporting shaft that was custom-made for the existing building. A lift was installed in the shaft that allows the users of the building, mainly a thrift store, to transport goods to the 1st floor.

Normally the lift is used only to transport goods, with a person to accompany the goods if desired. A fully enclosed cabin was built, ensuring the safety of the goods and people. Persons with disabilities can also safely use the goods lifts because of this.

Read more about the complete process below or view more photos at the bottom of the page.

Would you like to know more about this project or our Goods Lifts?

Application

For a multifunctional building in Germany, the municipality issued a tender for the lifts in the building. This tender was won by our German colleague Volkslift, who subsequently approached us to actually design and supply these lift. Since the requirements were too specific for a standard solution, Hublift was called in.

The multi-purpose building is used by several visitors and since it houses a thrift store, a goods lift was necessary. The goods lift also had to meet strict safety requirements as people also have to be transported.

User-friendliness and stability of the platform were decisive requirements. Also, reliability was very important, since the lift.

Design

Hublift builds no nonsense goods lifts, the design phase is essential to create a good understanding of the customer’s needs. Once we have a good understanding of the needs, we advise our customers on how the lift will best suit their needs and how the customer can work most efficiently with the lift. These considerations are all incorporated into the design of our lifts.

The customer was looking for a suitable design, different from a normal passenger lift or goods lift. Safety, ease of use and stability were high on the customer’s priority list. Together with the contractor, a product was developed based on a comprehensive set of requirements that exactly matched the architect’s design and the customer’s requirements.

By means of the hand control in the cabin, the lift can be used by persons who may be seated together with the goods in the lift.

Installation

Installing a lift like this one is not particularly difficult. This is a product with many components and electronic safeguards, however due to its relatively small size, they are quick to install. Our engineers started by building the self-supporting shaft, and after installing the hydraulic components and cabin, all the electronic components were installed and extensively tested.

In consultation with the customer, the installation work was planned in such a way as to cause as little disruption as possible. Other construction work on the building also took place during the installation of the lift. After testing the lift, the lift was delivered by our partner Volkslift to the customer, who then immediately put the lift into use.

Let’s Work Together

We are happy to give you free advice and ensure that your lift meets your needs. No bells and whistles that cause unnecessarily high prices, as we focus on the origin of the demand to create the lift that fits your needs perfectly.